- Parametric 3d modeling sofrtware update#

- Parametric 3d modeling sofrtware software#

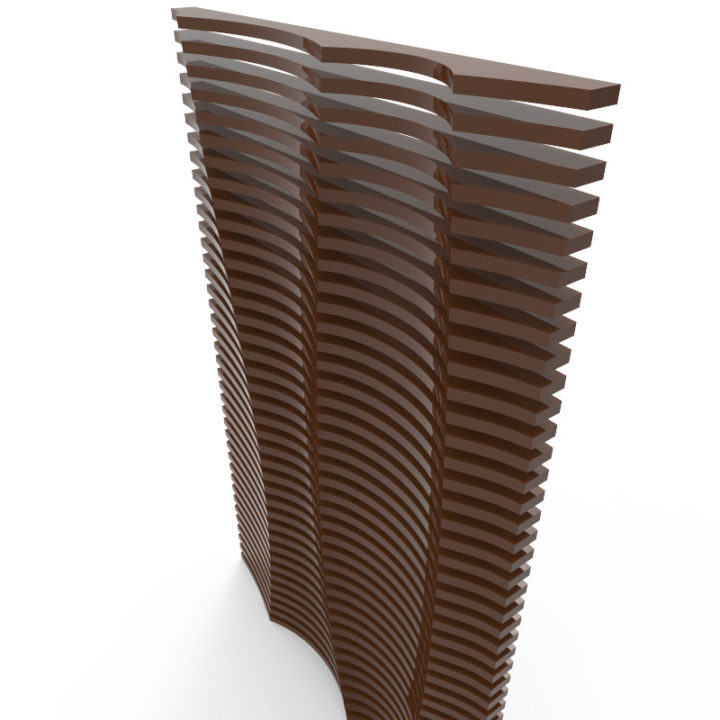

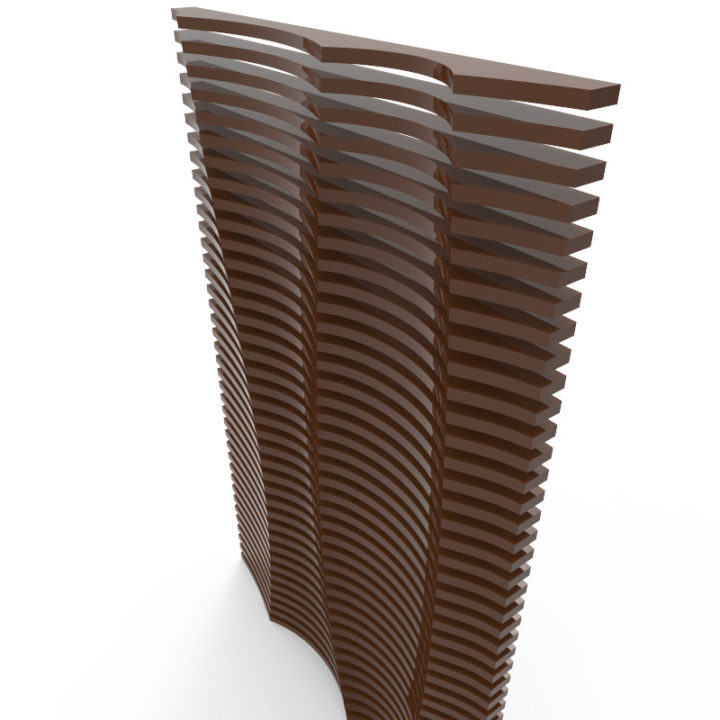

“It might make sense to use direct modeling during conceptual thinking, when you need to quickly manipulate the design and don’t want to be slowed down by working within pre-defined rules,” Schnitger added.

Parametric 3d modeling sofrtware software#

“Each approach, parametric or direct, has its uses and perhaps the perfect CAD strategy incorporates both,” CAD software industry analyst Monica Schnitger, president and founder of The Schnitger Corporation, has said.

Parametric 3d modeling sofrtware update#

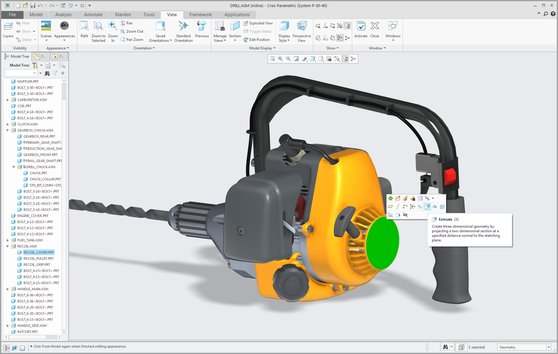

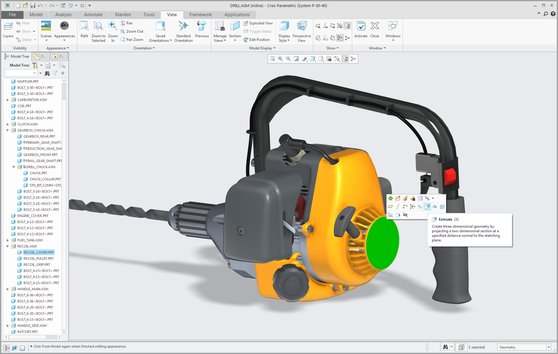

Parametric models take more time to update when unexpected design changes are needed.ĭirect modeling creates geometry rather than features so it supports that conceptual effort where the designer doesn’t want to be tied down with features and their inter-dependencies and the impact that making a change might have.Īsk the Expert: Monica Schnitger Weighs In. During concept design, parametric 3D CAD may be overkill for designers trying to investigate as many 3D concepts of an idea as quickly as possible. Some of the cons associated with parametric modeling include the following: Excellent integration with manufacturing processes, resulting in a decrease in production time.īut parametric technology is not without its drawbacks. Easy definition and automatic creation of families of parts. The ability to easily capture design intent, which makes it easier to define how the model should behave when something is changed. Automatic updates to the model if changes are made to the design. It also creates models with individual features that can be modified or changed - such as holes and chamfers - that are captured in a ‘model tree.’Ĭhampions of parametric modeling enjoy benefits that include: This supports designs that will need to be modified or iterated on a regular basis. For example, organizations often turn to parametric when making families of products that include slight variations on a core design, because the designer will need to create design intent between dimensions, parts and assemblies. Parametric Modeling technologies are a great fit for design tasks that involve exacting requirements and manufacturing criteria. Manufacturers that integrate direct modeling into their parametric environment report greater speed, quality, and focus on innovation that helps them stay ahead of the competition.īut before we talk about that, let’s weigh some of the pros and cons of direct and parametric modeling.

So which is better, direct or parametric? The answer is “all of the above.” While each has its benefits, the best CAD software uses both approaches to modeling. Simply push and pull the geometry until you arrive at just the shape you want. It is often compared to working with modeling clay.

What Is Direct Modeling?ĭirect modeling empowers you to define and capture geometry quickly, without spending time worrying about features, constraints, and original design intent.

Parametric modeling is an approach to 3D CAD in which you capture design intent using features and constraints, and this allows users to automate repetitive changes, such as those found in families of product parts. Some like the freedom and flexibility of direct modeling, while others prefer the feature definition and dimension control capabilities associated with parametric systems. Engineers have long debated the virtues of parametric versus direct modeling.

0 kommentar(er)

0 kommentar(er)